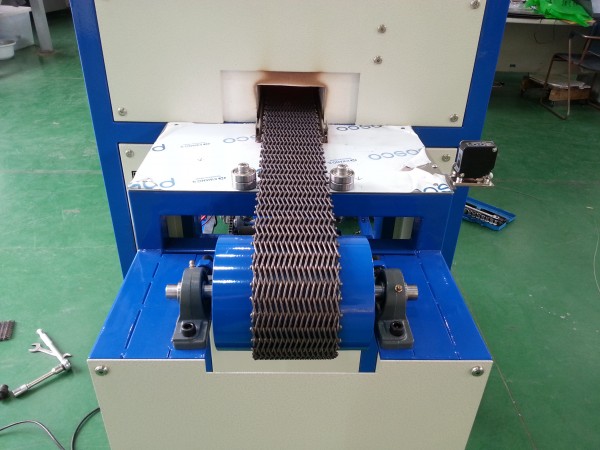

연속식 전기로(연속로) Continuous Chain Conveyor Kiln / Model KBL-4000-1000

General Specifications ( 기본사양 )

1.1 Oven Type ( 형태 ) : Continuous Type chain Conveyer Kiln

1.2 Applications ( 사용용도 ) : Firing for Ceramic Products

1.3 Maximum temperature ( 최고온도 ) : 1050

1.3.1 Working temperature ( 사용온도 ) : 1000

1.4 Conveyor Mechanism : Chain Conveyor

1.5 Heating Elements ( 발열체의 종류 )

1.5.1 Heat Section (건조구간) : Kanthal A1 Heating Element(Molding type)

1.5.2 Metal Muffle : Inconel 601, Appr. 3t, 42.5/48.6(ID/OD)x550mmL(4ea)

1.6 Process Atmosphere ( 사용 분위기 ) : Air

1.7 Overall Demension ( 외부크기 ) : Appr. 1400 H x 1000W x 3650L (mm)

1.8 Heated Cavity ( 가열로 용적 )

1.8.1 Chamber Size : Appr. 60ID hole x 550mmL x 4 zones

1.8.1.1 External Size : Appr. 165mm x 250mmH x 550mmL(4 ea)

1.8.1.2 Opening Size : Appr. 10mmH x 550mmL(4 ea)

1.8.2 Heat Section ( 소성 구간 ) : Appr. 550 x 4 = 2200mmL

1.8.2.1. Number of Zones : 4 zones

1.8.2.2. Temperature sensor : Type "K"(4 ea)

1.9 Insulating Materials ( 내화재의 종류 )

alumina castable block

** 상기 내화재의 축로 두께는 작업 조건에 따라 변경이 있음.

1.10 Control Instrumentation ( 온도 조절기 ) : 4 lot

4 lot - Delta model DTA-9696, SCR Power Control & electric equipment

1.11 Number of Control Zone ( 온도 조절 구간 ) : 4 zones

4 zones - Hi-Heating

1.14 Electrical Voltage ( 전 원 ) : 220V, 1phase, 60Hz

1.15 Maximum Power ( 최대전력 ) : Appr. 9.6 Kw(2.4Kw x 4 zones)